|

|

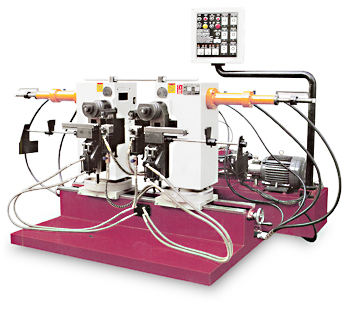

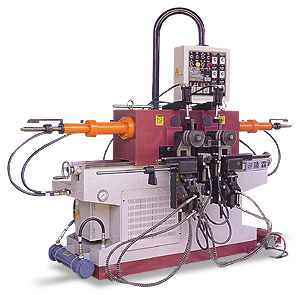

Double Finishing & Double-Bend Matel Tube Bender

|

|

This machine (CR-F38) is an improvement of CR-T38. It is capable of providing more than 3 different processing methods and is called "universal machine" in the field of double-bend processing. The mac

|

| |

|

Double Finishing & Double-Bend Matel Tube Bender

|

|

This machine (CR-F38) is an improvement of CR-T38. It is capable of providing more than 3 different processing methods and is called "universal machine" in the field of double-bend processing. The mac

|

| |

|

Double-Bending Matel Tube Bender

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

|

|

|

Double-Bending Matel Tube Bender

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

| |

|

Double-Bending Matel Tube Bender

|

|

This machine adopts proportional pressure control system. You can bend 2 pipes with two shafts synchronously, so The final product has precise dimensions and an attractive, wrinkle-free appearance. Th

|

| |

|

|

| |

| |

|

NC Push Bottom Panel〈SQ Series〉

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

|