|

| |

| |

|

|

|

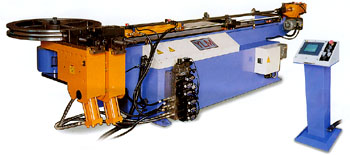

NC Push Bottom Panel〈SQ Series〉

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

| |

|

NC Push Bottom Panel〈SQ Series〉

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

| |

|

NC Push Bottom Panel〈SQ Series〉

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

|

|

|

NC Push Bottom Panel〈TSQ Series〉

|

|

FEATURES: Adopting solenoid valve and integrated circuit to control individual motion separately. Extending the life of the hydraulic system parts. Three step hydraulic oil flow system combines the fu

|

| |

|

Riveting Machine

|

|

CHARACTERISTICS: Fine micro-adjustment device can precisely adjust the range of the main axes, speed, pressure and time. Noiseless, no vibration, stabilized riveting quality. Mould changing is very ea

|

| |

|

Riveting Machine

|

|

CHARACTERISTICS: Fine micro-adjustment device can precisely adjust the range of the main axes, speed, pressure and time. Noiseless, no vibration, stabilized riveting quality. Mould changing is very ea

|

|