|

|

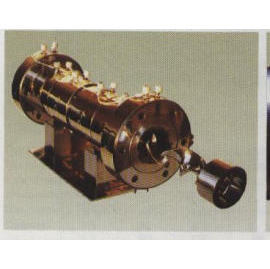

Статический смеситель для N60

|

|

This standard model is widely used for mixing, dispersion, dilution, neutralization and extraction. N60 type is used for laminar,turbulent and transitional flow applications. N60 model hasa six eleme

|

|

|

|

Статический смеситель для N60

|

|

This standard model is widely used for mixing, dispersion, dilution, neutralization and extraction. N60 type is used for laminar,turbulent and transitional flow applications. N60 model hasa six eleme

|

|

|

|

Статический смеситель для N60

|

|

This standard model is widely used for mixing, dispersion, dilution, neutralization and extraction. N60 type is used for laminar,turbulent and transitional flow applications. N60 model hasa six eleme

|

|

|

|

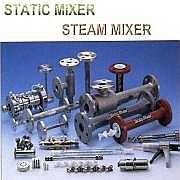

Статические смесители, паровые смесители

|

|

Static Mixer consists of a housing pipe and non-moving mixing elements. Fluids are mixed while passing through the mixer. Suitable for various range of mixing processes in the oil refining,chemical,p

|

|

|

|

Паровые смесители для МСБ-V Series

|

|

The steam mixer directly injects a steam into a liquid to heat the liquid. It comprises of a steam injection nozzle and a spiral element for diffusion and condensation. As it uses an in-line, spiral

|

|

|

|

Паровые смесители для МСБ-V Series

|

|

The steam mixer directly injects a steam into a liquid to heat the liquid. It comprises of a steam injection nozzle and a spiral element for diffusion and condensation. As it uses an in-line, spiral

|

|

|

|

Паровые смесители для МСБ-V Series

|

|

The steam mixer directly injects a steam into a liquid to heat the liquid. It comprises of a steam injection nozzle and a spiral element for diffusion and condensation. As it uses an in-line, spiral

|

|

|

|

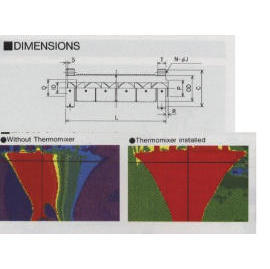

Thermomixer

|

|

STANDARD SPECIFICATIONS Size : 1``~4`` Material : Barrel :SCM435 Element: SUS316 No. of Elements: 6Elements Surface Finish : Barrel: Hard Chrome Plating (Inner Surface) Element: Buffing#400 Fittings

|

|

|

|

Thermomixer

|

|

The Noritake Thermomixer is a unique device developed for temperature homogenization and the strict temperature control of molten thermoplastics. Use of the appropriate Thermomixer solves the problem

|

|