|

|

Single-Bending Metal Tube Bender With Mandrel

|

|

Adopting solenoid valve and integrated circuit to control every motion separately. That extends the life of the parts of hydraulicsystem. Three-step circuit is with the functions of cooling & sediment

|

| |

|

Tube End-Forming Machine

|

|

Suitable for the shrinking of various metal pipes with 1. Different material and 2. Different shape. All parts are produced under very strict quality control, maintaining machine quality and standard

|

| |

|

Tube End-Forming Machine

|

|

Suitable for the shrinking of various metal pipes with 1. Different material and 2. Different shape. All parts are produced under very strict quality control, maintaining machine quality and standard

|

|

|

|

Tube End-Forming Machine

|

|

Suitable for the tube end-forming of various metal materials.All the parts are made under very strict quality control, so the quality of machine is in high level and the specification is standardized.

|

| |

|

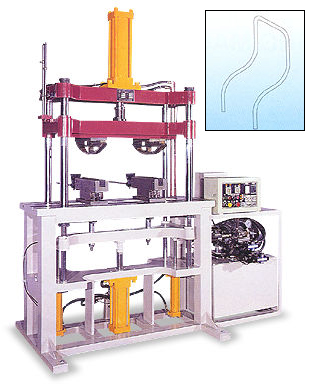

Tube Press Bending Machine

|

|

CR-M38: (1) The machine is designed for dual-working on U-shaped pipes with a larger bending radius that cannot be handled by the double-bending pipe bender. (2) 1~2 different bending angles can be se

|

| |

|

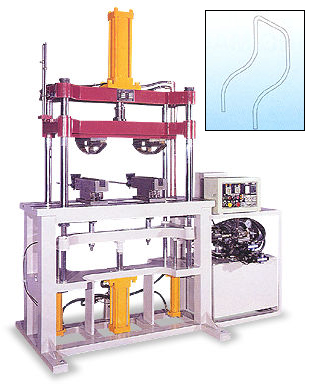

Tube Press Bending Machine

|

|

CR-M38: (1) The machine is designed for dual-working on U-shaped pipes with a larger bending radius that cannot be handled by the double-bending pipe bender. (2) 1~2 different bending angles can be se

|

|

|

|

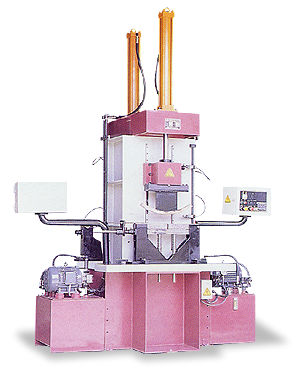

Tube Press Bending Machine

|

|

CR-M38A1 and CR-M38A2: (1) Both are designed for very special and complicated workpieces which are produced at slow speeds by other pipe benders. For example: (A) Finished pipes with a very large bend

|

| |

| |

|

Circle Rolling Machine

|

|

Bending speed can be adjusted freely from 1.5 seconds every 300mm to 5 seconds every 300mm. Bending diameter can be adjusted freely from 250mm to 2000mm. As to special requirements (smaller than 250mm

|

|