|

|

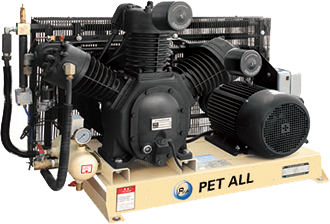

Booster Compressor

|

|

Booster ApplicationsCompressed air systems in industrial and commercial facilities are generally designed for pressures of 90 to 100psig . However,some special applications such as moulding, printing,

|

| |

| |

|

Oil Free Compressor

|

|

An automatic unload system ensures that the system starts safely without residual pressureThis feature protects both frame and motor and so extends the working life of all componentsHeavy-duty design

|

|

|

|

Piston Air Compressor

|

|

Automatic unload system to ensure the machine starts safety under unload circs, this way can extend the using life of air compressor and protect the mainframe and motorThe movement parts use the lubri

|

| |

|

Portable Screw Compressor

|

|

Ø Micrcomputer control systemØ Complete protection function with fault alarm and indicationØ Efficient filtering and seperating systemØ Efficient air-cooled enclosed motorØ Super Low Noise

|

| |

|

Water-cooling Air Compressor

|

|

Air compressor use water cooling system, high performance middle and after cooler4 Micron inlet filter ensure the chean airSpecially designed water cooling method ensure the compressorTrue full-day 24

|

|

|

|

2 Stage High Pressure Air Compressor

|

|

Two level noise reduction, less noiseIntegrated pipeline, whole machine more perfectPressure sensor makes exhaust pressure accurate, adjustment convently, fiferential pressure less than 0.5kg/cmEvery

|

| |

|