|

|

Koma Printer System

|

|

1. Material-in by heaping 2. Image focus automatically 3. Platform designs for fruitful production line 4. Constant pressure print 5. Automatic mending glue system 6. Installation of collecting mater

|

| |

|

Laser Vision measurement

|

|

1.All operations are easy and using Window`s interface in Chinese/English version. 2.Survey thickness of tin solder by automatically or manully. 3.Survey the length and width manually, ,and the gap o

|

| |

|

Laser Vision measurement

|

|

1.All operations are easy and using Window`s interface in Chinese/English version. 2.Survey thickness of tin solder by automatically or manully. 3.Survey the length and width manually, ,and the gap o

|

|

|

|

Low Temperature Cooling Spear

|

|

Feature: 1. Efficiency to low the temperature and to cool. 2. Improve processing quality 3. Reduce damage of cutting tool 4. Easy to install and operate. Application: 1. Dry cutting process. 2. Proce

|

| |

|

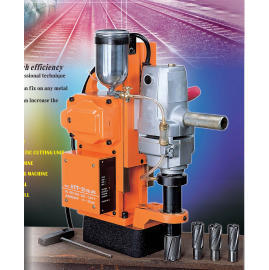

MAGNETIC DRILLING MACHINE

|

|

HIGH PRECISION WITH HIGH EFFICIENCY * SAVE THE LABOUR, NOT NEED PROFESSIONAL TECHNIQUE TO CUT OUT THE PROFESSIONAL HOLE. * THE SUCTION IS VERY STRONG. IT CAN FIX ON ANY METAL MAGNETIC FORCE PLATFORM.

|

| |

|

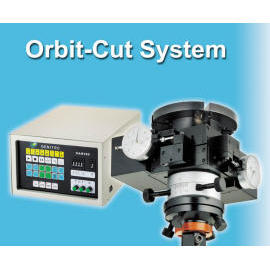

Orbit-Cut System

|

|

1.The best helper with low cost, high efficiency and quality. 2.Full digital and micro step control system with high precision. 3.Fit in with all kinds of EDM. 4.Combination operation for selling mul

|

|

|

|

Pneumatic Stencil/PCB Clean Machine

|

|

1.Aerodynamic controlled, thus there will be no problem about burn point in using solvent. 2.Only needs 9 minutes to wish and dry automatically filter and recycle the solvent. 3.To sure the cleanline

|

| |

|

Positive Displacement Injection systems

|

|

1.It can provide the steady flow rate to lubricate the particular position every cycle. 2.The oil viscosity and lubricating time won`t affect the flow rate.

|

| |

|

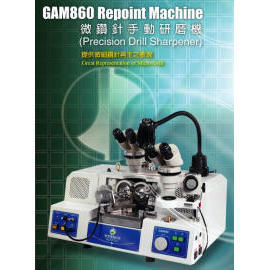

Precision Drill Sharpener

|

|

1.Suitable for SMT`s small diameter of drill, to do the second grind. 2.Just need to fit in an opposite position for one time, an operator could grind. 3.When the grinds has finished, the press-plate

|

|