|

|

Feeding Section

|

|

- Sun Lead Edge Feeder for accurate registration for all flutes & micro-flutes and warp sheets - Skip feed and feed interrupt capability - Frequency inverter drive for variable vacuum control - Auto-

|

| |

|

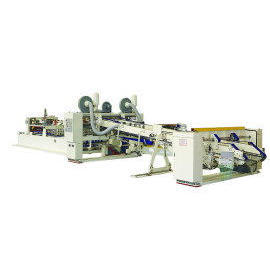

Flexo Folder Gluer

|

|

- High flexo graphic printing image and quality at registration accuracy +/- 0.25mm. With dual ink chamber blade system as stand supply - Order change during other printer units in production. Operat

|

| |

|

Folder Gluer

|

|

- Up folding or down folding depends on top or bottom print with extended folding length to eliminates fishtailing - Full length vacuum belts for accurate gap control - Independent closed loop vector

|

|

|

|

Mill Roll Stand

|

|

- Type: hydraulic (swing type) - Working size: max. paper roll dia. 1500mm, min. paper roll dia. 330mm. - Clamp arms with electric push-button and magnetic switch to operate right-left-front-back dir

|

| |

|

N.C. Cut Off

|

|

- Machine speed: 70 m/min. to 250 m/min. depends on the speed curve chart as well as the motor capacity quoted - Main drive motor: 77 KW or 130 KW AC servo motor from Italy with 9KW or 132 KW regen s

|

| |

|

Printing Section

|

|

BOTTOM PRINT - P1000, P1200, P1600, P2200) - Bottom print with vacuum transfer for accurate color to color registration on P1000, P1200 and P1600 series - Use planetary gear system for running regist

|

|

|

|

Single Facer

|

|

General: - Cartridge mounted corrugating roll for quick flute change - Vacuum or pressure type - Speed to 350 mpm (1150 fpm) - Main power AC motor with AC inverter for energy savings - Direct Gates G

|

| |

|

Auto Down Stacker

|

|

- Hydraulic unit control for stacking table up and down movement - Use hydraulic power unit with 20HP motor - Pallet delivery conveyor x 1 unit - Pile of sheets delivery conveyor x 1 unit - Sheet shi

|

| |

|

Auto Splicer

|

|

- Design splicing speed 150m/min. - For swing type mill roll stand - Precision electronic tension control on tension roll to obtain stable spliing - Tail grabbing device lets splicing start when pape

|

|