|

|

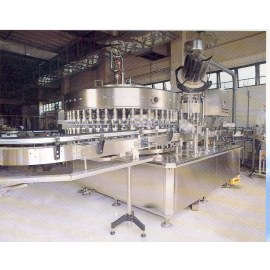

FULLY AUTOMATIC FILLER CAPPER

|

|

1.Production capacity up to 120-300 bottles per minute. 2.Bottle infeed and discharge motions are stable and smooth. 3.The frequency inverter control combined with digital speed display provides accu

|

| |

|

FULLY AUTOMATIC FILLER CAPPER

|

|

1.Production capacity up to 120-300 bottles per minute. 2.Bottle infeed and discharge motions are stable and smooth. 3.The frequency inverter control combined with digital speed display provides accu

|

| |

|

|

| |

|

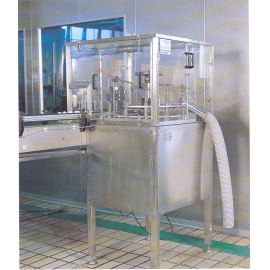

INDUCTION ALUMINUM FOIL SEALING MACHINE

|

|

1.The detector checks for the presence of foil. It sends a signal when foil is missed on a certain cap. This prevents unsealed products from being delivered. 2.Safe in use. The machine is built with

|

| |

|

RAW COFFEE BEAN DE-SHELLING MACHINE

|

|

DISIGNED FOR ELIMINATING THE TROUBLESOME BEAN WASHING PROCESS THIS MACHINE REDUCES LABOR COSTS WHILE CREATING EXCELLENT QUALITY COFFEE BEANS

|

|

|

|

Raw Coffee Bean De-Shelling sorting machine

|

|

This machine combines de-shelling and sorting functions in one, featuring high efficiency and high production capacity. It greatly saves labor costs while providing maximum convenience for coffee bea

|

| |

|

Raw Coffee Bean De-Shelling sorting machine

|

|

This machine combines de-shelling and sorting functions in one, featuring high efficiency and high production capacity. It greatly saves labor costs while providing maximum convenience for coffee bea

|

| |

|

BOTTLE MOUTH CUTTING MACHINE

|

|

Before filing operation, all empty bottle mouths should be cut on this machine to eliminate pollution. Change of bottle size is simply made by adjusting the gap and height only.Maximum production rat

|

|